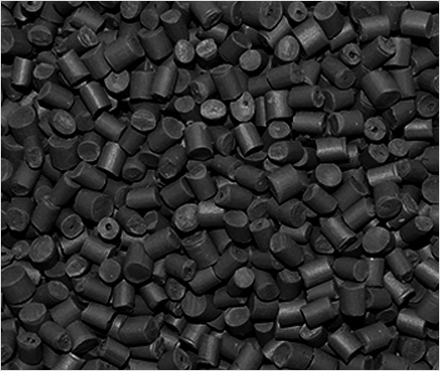

ATP starts the LSZH compound ( LSOH material ) research and development for various applications such as Rail Transit, Architecture&Home Decoration, data communication, based on the CRP (European Construction Products Regulation) requirement from 2017;

ATP's low smoke zero halogen materials support the wire and cables to pass the CPR EN50575 grade (B2ca, Cca, Dca, Eca) burning test;

The LSZH jacket material has a higher flame retardant grade and drop test grade, and still has excellent processing characteristics and quality under the condition of high flame retardant performance;

ATP's High Voltage LSOH LSZH Cable Jacket Material Solution, Fully meets the low friction LSZH requirements of temperature resistance, flame retardant, and other indicators of high-voltage wire harness passing ISO 6722 125 ℃ and ISO6722 125℃ tests.

LSZH materials are used in various applications where smoke emission and toxicity caused by burning of the materials can be a safety hazard, such as in aircraft, trains, ships, data centers, and public spaces.

What is LSZH?LSZH materials are made from special polymers that contain no halogenated additives, which are responsible for producing smoke and toxic fumes when the material is burned. Instead, LSZH materials are formulated with fire retardant chemicals that reduce the amount of smoke and toxic gases emitted during a fire.

LSZH materials are preferred in situations where human safety is of utmost importance, as well as in settings where sensitive electronic equipment is present, as smoke and corrosive gases can damage electronic components. LSZH materials are also more environmentally friendly compared to traditional halogenated materials, as they release fewer harmful substances into the environment when burned.

Low Smoke Zero Halogen (LSZH) materials are used in a variety of applications where the release of smoke and harmful gases could pose a threat to human life or equipment. Here are some benefits of this material:

Less Toxicity: LSZH materials contain no halogens, which are known to emit toxic gases when burned. This makes them ideal for use in confined spaces such as aircraft cabins, submarines, and underground tunnels where the accumulation of toxic gases can pose a serious risk to human life.

Increased Safety: In addition to reducing toxicity, LSZH materials also reduce the amount of smoke produced during combustion. This helps to minimize the risk of smoke inhalation, which can cause serious health problems and impair visibility in emergency situations.

Improved Equipment Protection: LSZH materials are also beneficial for protecting equipment in the event of a fire. Since they produce less smoke, they can help to prevent smoke damage to sensitive electronic equipment, which can be costly to replace.

Environmental Friendliness: LSZH materials are also environmentally friendly, as they do not emit toxic gases when burned. This makes them a good choice for use in applications where sustainability and eco-friendliness are important considerations.

Compliance with Regulations: Many industries, including aerospace, transportation, and telecommunications, have regulations that require the use of LSZH materials in certain applications. Choosing LSZH materials can help ensure compliance with these regulations and avoid costly fines or other penalties.

LSZH (Low Smoke Zero Halogen) materials are used in a variety of applications where fire safety, low smoke emissions, and minimal toxicity are critical.

1. Telecommunications Cables

Low smoke zero halogen materials are essential in telecommunications cables, where their fire-resistant properties help prevent the release of toxic gases during a fire. The use of LSZH/LSOH cables ensures safety in communication infrastructure, particularly in high-density areas like office buildings, hospitals, and airports. These low smoke zero halogen materials are crucial for protecting both people and equipment in emergencies.

2. Electrical Cables

Electrical wiring in buildings and vehicles often incorporates low smoke zero halogen material for enhanced fire safety. In case of a fire, LSZH/LSOH cables significantly reduce smoke emissions and toxic fumes, which is critical for ensuring the safety of occupants and emergency responders. These materials are especially important in high-risk areas such as tunnels and public transport systems.

3. Automotive Industry

In the automotive sector, low smoke zero halogen LSZH materials are increasingly used for wiring and interior components. Their ability to resist fire while minimizing the release of toxic gases makes them an essential choice for electric vehicles and modern automobiles. The use of LSZH/LSOH materials in engine compartments and wiring harnesses enhances the overall safety of the vehicle in the event of a fire.

4. Construction and Building Interiors

Low smoke zero halogen material plays a vital role in construction and interior design, especially in areas with strict fire safety regulations. These materials are used for wiring, insulation, and flooring to limit the spread of flames and reduce smoke toxicity. Low smoke zero halogen LSZH materials are commonly found in public buildings like hospitals, schools, and airports, where safety is paramount.

5. Marine Applications

Low smoke zero halogen LSZH materials are crucial for safety in marine applications, including ships, offshore platforms, and submarines. The use of LSZH/LSOH cables and components ensures that, in the event of a fire, the release of toxic gases and smoke is minimized, safeguarding both the crew and passengers. These materials are integral to meeting maritime safety standards.

Deep Industry Roots: Founded in 2007 by a distinguished team of polymer materials experts, ATP Polymer boasts a strong foundation built upon years of collective industry experience. This deep understanding of polymer science and material behavior allows ATP Polymer to consistently deliver innovative and high-performance LSOH/LSZH solutions.

Cutting-Edge Technology: The company possesses a state-of-the-art testing facility equipped with industry-leading equipment for comprehensive material performance analysis. This includes specialized equipment in South China specifically designed to meet the stringent requirements of European Union CPR regulations and GB31247 cable flame retardant standards.

Manufacturing Excellence: ATP Polymer leverages intelligent manufacturing capabilities and robust quality control systems to ensure consistent product quality and adherence to ISO 9001:2015 and ISO 14001 standards.

Production Capacity: With an annual design capacity of nearly 12,000 tons, ATP Polymer is well-positioned to meet the growing demand for high-quality LSZH materials across various industries.

Customer Focus: ATP Polymer is deeply committed to customer satisfaction. The company strives to build long-term partnerships with its customers by understanding their unique needs and providing tailored and customized solutions that exceed expectations.

Very effective solution of total heat released and peak heat release rate control. The higher carbon deposition efficiency, that refers to the quickly carburized of the cable surface while burning, an effective protective layer is formed; Smoke generation and halogen gas release while burning fully to meet the requirements of the regulations; Fully support optical cables, cables, and network cables to pass various combustion tests( different product designations meeting different levels of burning tests) of EN 50575 (B2ca level, Cca level, Dca level) and GB31247 (except A level).

Fully support cables, optical cables, and network cables to pass the LSZH LSOH environmental resistance tests like cracking, aging tests in high-temperature situations, UV aging; winding, and impacting tests in low-temperature situations.

Better wear resistance and scratch resistance than the others in the same LSOH material testing condition.

Fully meet the requirements of high-speed extruding, line diameter rounded and stable, less salivation (less die stock), good color stability, and higher yield rate. Batch stability and homogeneity are guaranteed.

High-flame retardant LSZH: support EU CPR regulation and Chinese GB31247;

High hardness LSZH: hardness ≥65D, or ≥98A; support a wide range of operating temperature of -40~125℃;

Low friction LSZH: Low friction for convenient site operation;

High-temperature resistant LSZH: Non-sticky for 125℃/1000 Hrs;

High-temperature resistant and shrinkage-resistant LSZH: 1) shrinkage≤5‰ under high-temperature cycling at 85℃; 2) shrinkage≤5‰ under low-temperature cycling at -40℃; 3) High and low-temperature shrinkage: shrinkage≤5‰ under high and low-temperature cycling at -40~85℃; 4) support a wide range of long-term operating temperature -40~125℃;

Radiation cross-linked LSZH: Temperature class will be greatly raised after radiation cross-linking, and supports the high-temperature cables to meet the requirements of flame retardant and long-term aging tests at 150℃-temperature resistance grade;

UV cross-linked LSZH: UV lamp radiational low smoke zero halogen material is suitable for scale and high-efficiency quantity production of thin-wall insulation of cables.

Yes, LSZH is generally better than PVC in terms of fire safety. LSZH (Low Smoke Zero Halogen) materials emit minimal smoke and no toxic gases when burned, reducing health risks in case of a fire. PVC, on the other hand, releases harmful halogen gases, making LSZH the safer choice in critical environments.

Yes, LSZH materials are considered more environmentally friendly compared to traditional halogenated materials. They are halogen-free, which means they do not release toxic gases like chlorine or bromine when burned, reducing their environmental impact. Additionally, they are safer to dispose of as they do not pose the same risks of soil or water contamination.

The usual MOQ is 1 ton, but it can vary. Please check with our sales team for exact quantities. Orders typically take 30-40 days to be produced and delivered.