Thermoplastic Polyurethane (TPU) material is revolutionizing industries worldwide with its exceptional properties and wide-ranging applications. In this blog, we'll delve into what TPU material is, its unique characteristics, and the diverse industries that benefit from its versatility.

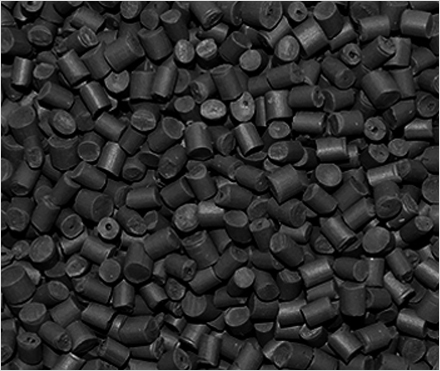

TPU is a type of elastomer that combines the elasticity of rubber with the processability of thermoplastics. It is synthesized through the reaction of diisocyanates with polyols, resulting in a polymer with alternating hard and soft segments. This molecular structure gives TPU its remarkable properties, including:

TPU exhibits outstanding flexibility and elasticity, allowing it to be stretched, bent, and compressed without permanent deformation. This property makes it ideal for applications requiring resilience and durability, such as in footwear, sporting goods, and medical devices.

TPU is highly resistant to abrasion, making it suitable for applications where wear and tear are common. It maintains its integrity even after prolonged use, ensuring longevity and reliability in products like conveyor belts, automotive parts, and protective gear.

TPU demonstrates excellent resistance to a wide range of chemicals, including oils, greases, and solvents. This makes it suitable for use in industrial applications where exposure to harsh chemicals is prevalent, such as in hoses, seals, and gaskets.

TPU boasts outstanding weatherability, retaining its properties over a broad temperature range and resisting degradation from UV radiation and ozone exposure. This makes it a preferred choice for outdoor applications, including automotive parts, marine equipment, and outdoor apparel.

TPU can be processed using various methods, including injection molding, extrusion, and blow molding. Its versatility in processing techniques allows for the production of intricate shapes and designs, making TPU suitable for a wide range of applications.

TPU's unique combination of properties makes it a versatile solution for a diverse range of industries:

TPU is widely used in footwear for its flexibility, durability, and abrasion resistance. It is commonly found in shoe soles, midsoles, and uppers, providing comfort and support to users.

In the automotive industry, TPU is used in various applications, including interior components, seals, gaskets, and under-the-hood parts. Its resilience to abrasion, chemicals, and weathering makes it a preferred choice for automotive manufacturers.

TPU's biocompatibility and flexibility make it suitable for use in medical devices, such as tubing, catheters, and wound dressings. Its resistance to chemicals and sterilization methods ensures safety and reliability in healthcare settings.

TPU is used in a wide range of consumer goods, including phone cases, protective covers, and sports equipment. Its soft-touch feel, durability, and resistance to wear make it a popular choice for manufacturers seeking high-quality materials.

TPU is employed in various industrial applications, such as conveyor belts, hoses, seals, and gaskets. Its resistance to abrasion, chemicals, and weathering ensures reliable performance in demanding environments.

Thermoplastic Polyurethane (TPU) material offers a unique combination of flexibility, durability, and processability, making it a versatile solution for diverse applications across multiple industries. Whether in footwear, automotive, medical devices, consumer goods, or industrial applications, TPU continues to drive innovation and enhance product performance worldwide. As technology advances and material science evolves, the potential applications and benefits of TPU material are expected to expand even further, cementing its position as a leading material of choice for manufacturers seeking high-performance solutions.