In the realm of materials used in everyday products, TPU (Thermoplastic Polyurethane) and silicone are two commonly encountered terms. Both are versatile substances with unique properties, finding applications in various industries from consumer goods to medical devices. Yet, understanding the disparities between TPU and silicone is crucial for selecting the right material for specific purposes. Let’s delve into the characteristics of each to shed light on their differences.

TPU is a type of thermoplastic elastomer known for its exceptional elasticity, durability, and resistance to abrasion. It is created through the reaction of diisocyanates with polyols, resulting in a material that combines the flexibility of rubber with the processability of thermoplastics. Here are some key features of TPU:

Flexibility and Elasticity: TPU exhibits high elasticity, allowing it to stretch significantly without losing its shape or integrity. This property makes it suitable for applications requiring flexibility and resilience, such as phone cases, sportswear, and medical tubing.

Abrasion Resistance: TPU is highly resistant to abrasion, making it ideal for products subjected to wear and tear. From protective coatings on cables to durable shoe soles, TPU enhances the longevity of various items.

Chemical Resistance: TPU offers good resistance to oils, greases, and solvents, contributing to its durability and suitability for industrial applications.

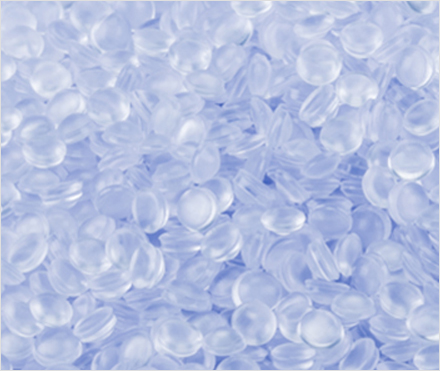

Transparency: Depending on its formulation, TPU can be transparent or opaque, providing versatility in design options for manufacturers.

Silicone, on the other hand, is a synthetic polymer made primarily from silicon, oxygen, carbon, and hydrogen. It possesses distinct properties that differentiate it from TPU:

Heat Resistance: Silicone exhibits exceptional heat resistance, remaining stable across a wide temperature range (-60°C to 230°C or higher). This property makes it suitable for applications involving exposure to extreme temperatures, such as oven mitts, baking molds, and automotive gaskets.

Flexibility and Softness: Silicone is inherently soft and flexible, offering a comfortable feel and excellent tactile properties. This characteristic makes it popular in various consumer products, including kitchen utensils, baby products, and medical devices.

Chemical Inertness: Silicone is highly inert and resistant to chemical degradation, making it safe for contact with food and pharmaceuticals. It does not react with most substances, ensuring product purity and longevity.

Water Repellency: Silicone is hydrophobic, repelling water and resisting moisture absorption. This property is advantageous in applications requiring waterproofing, such as sealants, gaskets, and outdoor gear.

Here's a simplified comparison chart highlighting the key differences between TPU (Thermoplastic Polyurethane) and silicone:

| Property | TPU | Silicone |

| Flexibility | Highly flexible and elastic | Soft and flexible |

| Heat Resistance | Moderate heat resistance | Excellent heat resistance |

| Abrasion Resistance | High abrasion resistance | Moderate abrasion resistance |

| Chemical Resistance | Good resistance to oils and solvents | Highly inert, resistant to chemicals |

| Transparency | Can be transparent or opaque | Generally translucent |

| Water Resistance | Moderate resistance to water | Highly hydrophobic, repels water |

| Applications | Phone cases, sportswear, medical tubing | Oven mitts, kitchen utensils, baby products |

| Protective coatings, shoe soles | Sealants, gaskets, medical devices |

In summary, while both TPU and silicone offer unique advantages, their distinct properties cater to different applications and requirements. TPU excels in elasticity, abrasion resistance, and chemical resistance, making it suitable for flexible, durable products. On the other hand, silicone boasts superior heat resistance, flexibility, and chemical inertness, making it a preferred choice for heat-resistant, soft-touch applications. Understanding these differences enables manufacturers and consumers to make informed decisions when selecting materials for specific purposes, ensuring optimal performance and functionality.